SERIES

Bend series

Tee series

Flange series

Reducer series

Simmer the bent pipe ser

Wear-resistant pipe fi

Plant accessories series

Ripple compensator seri

Pipe expander

Cleaner series

Piping support series

Head cap

Pipe series

Insulation series

Series of anti-corrosion

Concrete pump accessories seri

Plastic Lined Pipe Series

Surfacing machine / wire drawi

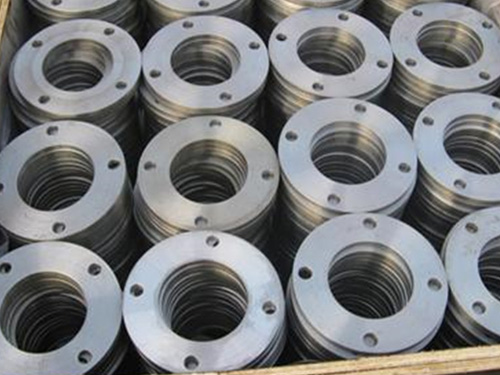

Flat welding flange

The flanged flanges are divided into two types: a-level welding flanges and type b flanges. Both flanges belong to arbitrary flanges. The flanged flanges should not be used in highly demanding situations such as flammable, explosive and high or extremely hazardous media. But for the low pressure, low temperature, working condition of non flammable and explosive, non-toxic medium pressure vessel flange, based on a (flat welding flange structure is more, because the flange structure has the processing is convenient, compact size, economical and practical characteristics. Due to the application range of standard a-level welding flange and the deviation of practical application, the standard a-level welding flange has some limitations.

Standard a-level welding flange materials are limited to 5 varieties of Q235A, Q235B, Q235C, Q245R and Q345R. In fact, the flanges of stainless steel are widely used in chemical industry, light industry, food, medicine and other industries. Different materials, the allowable stress of flanges is different, cannot simply apply standard flanges directly.

Flat welding flange is commonly referred to as the flat plate, also called lap welding flange. The connection between the flat welding flange and the pipe is to insert the tube into the flange hole to the proper position and then weld it again.

Flat welding flange is used for carbon steel pipe connection, nominal pressure not exceeding 2. 5 mpa, flat welding flange connection forms including one-side welding and double nut connection, the welding with one-side welding does not need to welded pipe and flange connection inside the mouth, is generally used in low and medium pressure piping.

The production process of flat welding flange: it is divided into pure material forging and wool forging (second). It is suitable for flat welding and welding flange, and the steel plate is suitable for flanging flange, as well as centrifugal casting and casting flange.

The characteristics of flat welding flange: the flat welding flange not only saves the space, reduces the weight, but more importantly ensures that the joint area does not leak and has good sealing performance. The compact flange size is reduced by reducing the diameter of the sealing part, which will reduce the cross-section of the sealing surface. Second, the flange gasket has been replaced by the sealing ring to ensure that the seal faces the sealing surface match. In this way, it only takes a little pressure to compress the cover. As the pressure required to reduce, the size of the bolt and the required quantity can be reduced accordingly, so the final design out a small volume and light weight (70% ~ 80% reduction in weight than traditional flange) of new products. Therefore, the flat welding flange is a kind of high quality flanged product, which reduces the quality and space and plays an important role in industrial use.

The sealing principle of flat welding flange: the two sealing surface of the bolt extrude flange gasket and form seal, but it also causes sealing damage. To keep the seal tight, it must maintain a large bolt force. For this purpose, the bolt must be larger. Larger bolts match larger nuts, which means larger bolts are needed to create conditions for tightening nuts. However, the larger the diameter of the bolt, the suitable flanges will become curved and the idea is to increase the wall thickness of the flanged part. The whole device will require a great deal of size and weight, which becomes a special issue in the offshore environment, because in this case the weight is always the main concern. And, fundamentally, flat welding flanges are an ineffective seal that requires 50 percent of the bolt load to be used to squeeze the gaskets, while the load that is used to keep the pressure is 50 percent.